POLYURETHANE - WHAT IS IT?

Polyurethanes are plastic materials used in a wide variety of applications to create all kinds of consumer and industrial products that make our lives more comfortable and environmentally friendly. Polyurethane is a product that most people are not overly familiar with, as it is generally 'hidden' behind covers or surfaces made of other materials.

Because polyurethanes are so versatile and known to be excellent insulators, they offer many solutions to the challenges of energy conservation and eco-design and they help to protect the environment by conserving energy. The polyurethanes industry is always seeking to reduce its impact on the environment and is currently exploring ways of increasing the energy efficiency of manufacturing processes and creating end products that can be used to save energy, such as building insulation.

We use polyurethanes in one form or another every day. They can be tailored to be either rigid or flexible for a wide range of end-user applications that show how versatile this material is, among which building insulation, refrigerators and freezers, footwear, furniture and bedding, the automotive sector, coatings, adhesives and many other applications.

Polyurethanes are found just about everywhere in modern life, from the relaxation provided by foams in furniture and bedding to the insulation that regulates temperature inside buildings and preserves the Earth’s natural resources by reducing the need for energy. Moreover, recycling and energy recovery options are available at the end of a polyurethane product's lifetime.

DUNA-Corradini polyurethane

DUNA-Corradini focuses on expanded rigid polyurethanes. Initially, we developed continuous-bunstock foams for thermal insulation (particularly in refrigerated trucks and cold cells), sold in sheets, blocks and special items. Shortly after, Duna-Corradini developed a wide range of two-component liquid systems to produce rigid foams by molding, spraying and pour-in-place techniques for a variety of applications, including discontinuous panel production, appliances, pipe and tank insulation, roofing, etc.

In addition to conventional rigid foam systems, Duna-Corradini also developed a range of polyurethane adhesives (glues) and packaging solutions, based on the use of semi-rigid polyurethane foams providing a self-forming protective packaging, with the help of a dosing machine designed and manufactured internally.

Beside polyurethane technology, DUNA-Corradini S.p.A. is also experienced in epoxy systems technology, offering both high-strength epoxy adhesives and specialties for natural stone treatment (reinforcing and finishing).

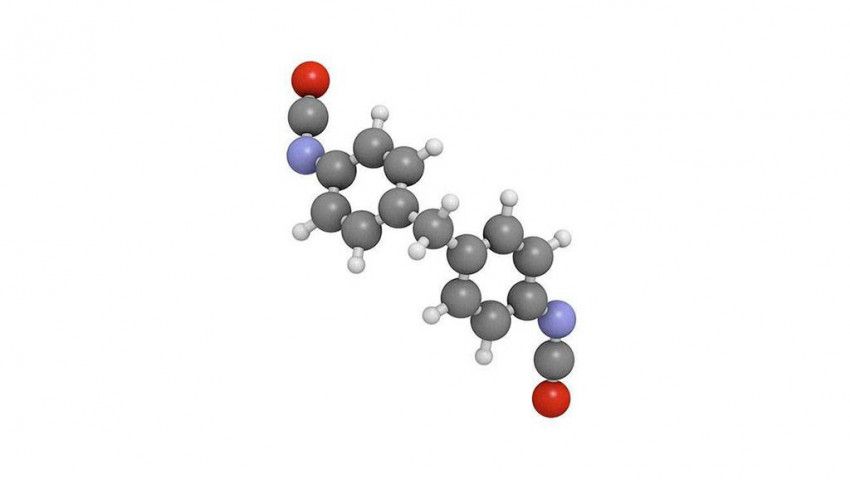

PU Basic Chemistry

Polyurethanes are polymeric materials, made by long molecular chains that are interconnected (cross-linked) to each-other; chains are obtained by the repeated linkage of two units: isocyanates (MDI) and polyols, generally obtained by mixing isocyanates and polyols in suitable ratios.

After mixing, a strongly-exothermic reaction of polymerization starts; this reaction is complete and does not yield any by-products; the reaction rate can be regulated by using special catalysts.

A huge variety of additives are used to adjust the final properties of the polyurethanes.

Heat released by the reaction is responsible for foam growth when a blowing agent is added: a blowing agent is a low-boiling point liquid or a gas that expands using the heat developed by the exothermic urethane reaction.

General Characteristics of Polyurethanes

- Thermo-setting polymers

- Chemically inert

- Biologically inert

- Good and versatile mechanical properties

- High thermal and electric insulator

- Excellent adhesion

Probably not everybody knows that...

- 9.6 cm thick polyurethane insulation has the same insulation efficiency as 80 cm of perforated bricks.

- The polyurethane industry employs over 800,000 people in 23,500 companies in the EU. If we include raw materials producers and related industries, figures increase to 3,021,400 employees and 94,685 companies.

- During their chemical reaction, Isocyanate and polyol expand up to 280 times their volume.

- The first polyurethane surfboard was made and used in the 1950s; today polyurethane replaces wood more and more in very many applications thanks to its resistance to humidity and deterioration, e.g. in signs.

- With the introduction of polyurethanes in refrigerators, models designated A++ today are 60% more efficient than 15 years ago.

- Polyurethane is often referred to as PU or PUR. PIR on the other hand refers to Polyisocyanurate foams, a particular kind of polyurethanes.

- Since 1995, all polyurethane foams have been CFC-free in the EU. Since 2003, they have been HCFC free as well, in order to reduce the ozone depletion potential.