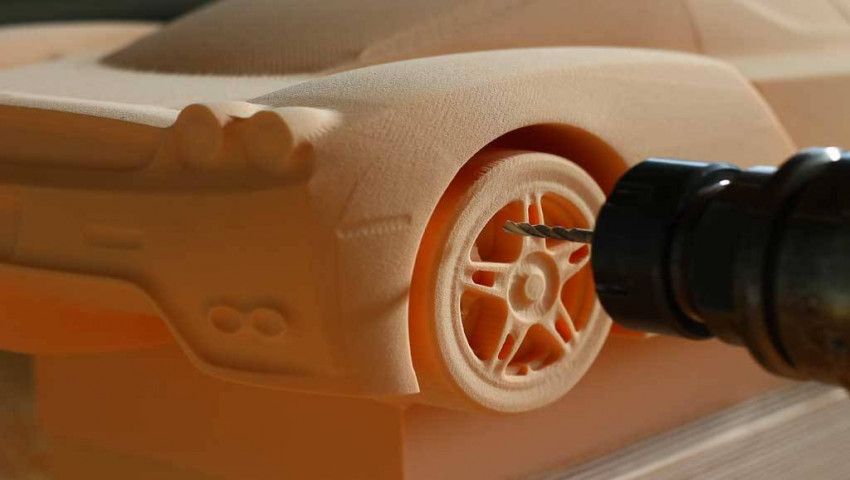

Appreciated in all fields of modeling, art and carving, design and rapid prototyping, this range of polyurethane and polyisocyanurate foams has some unequalled features, including its great workability, precision with outlines, resistance to mechanical stress, and availability in different densities (from 80 to 490 kg/m3).

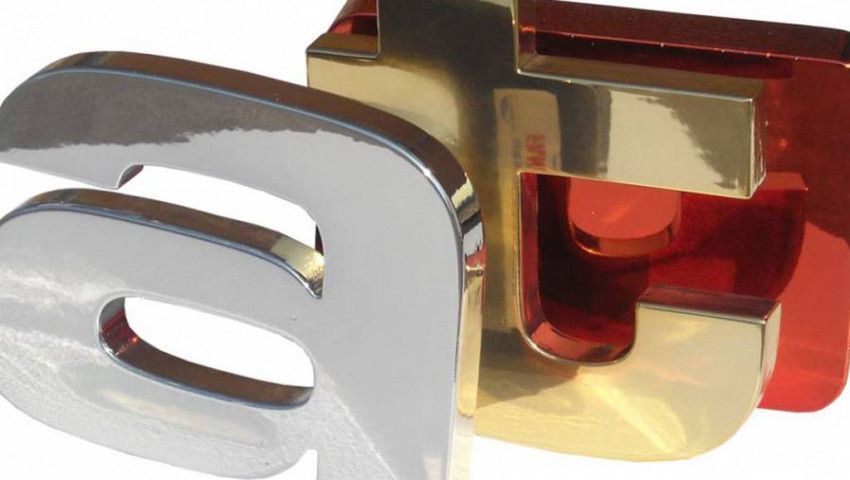

These features, together with their resistance to organic decay, atmospheric agents and salted air and the majority of solvents, have allowed polyurethane and polyisocyanurate foams to be the primary replacement for wood in many applications, among which art, tooling and signage.

Due to their resistance to mechanical stress and insulating power, polyurethanes and polyisocyanurates are also frequently used as supports in the cryogenic field.

| CORAFOAM® | Density (kg/m³) | Initial thermal conductivity at 10°C (mW/mK) | Parallel compressive resistance at 23°C (MPa) | Fire behaviour | Operating temperatures (°C) |

|---|---|---|---|---|---|

|

EN 1602 ASTM D1622 |

EN 12667 ASTM C518 |

EN 826 ASTM D1621 |

|||

| MD 80 | 80,0 | 23,0 | 1,1 |

DIN4102: B3 EN 13501: Euroclasse F |

-200/80 |

| MD 100 | 100,0 | 25,0 | 1,1 |

DIN4102: B3 EN 13501: Euroclasse F |

-200/80 |

| MD 140 | 140,0 | 30,0 | 1,7 |

DIN4102: B3 EN 13501: Euroclasse F |

-200/80 |

| MD 160 | 160,0 | 31,6 | 2,0 |

DIN4102: B3 EN 13501: Euroclasse F |

-200/80 |

| MD 200 | 200,0 | 36,5 | 2,9 |

DIN4102: B3 EN 13501: Euroclasse F |

-200/65 |

| MD 250 | 250,0 | 43,5 | 4,2 |

DIN4102: B3 EN 13501: Euroclasse F |

-200/65 |

| MD 300 | 300,0 | 47,0 | 6,0 |

DIN4102: B2 EN 13501: Euroclasse E |

-200/65 |

| MD 350 | 350,0 | 57,0 | 7,0 |

DIN4102: B2 EN 13501: Euroclasse E |

-200/65 |

| MD 400 | 415,0 | 63,0 | 12,2 |

DIN4102: B2 EN 13501: Euroclasse E |

-200/65 |

| MD 500 | 490,0 | 72,0 | 15,2 |

DIN4102: B2 EN 13501: Euroclasse E |

-200/65 |

| RTS 60 | 63,0 | 24,0 | 0,6 |

DIN4102: B2 EN 13501: Euroclasse E |

-200/120 |

| RTS 60V | 63,0 | 22,2 | 0,6 |

DIN4102: B2 EN 13501: Euroclasse E |

-200/120 |

| RTS 80 V | 83,0 | 22,2 | 0,9 |

DIN4102: B2 EN 13501: Euroclasse E |

-200/120 |

| RTS 120 | 120,0 | 25,9 | 1,6 |

DIN4102: B2 EN 13501: Euroclasse E |

-200/120 |

| RTS 120 D | 120,0 | 28,0 | 1,6 |

DIN4102: B2 EN 13501: Euroclasse E |

-200/120 |

| RTS 140 | 140,0 | 29,9 | 2,0 |

DIN4102: B2 EN 13501: Euroclasse E |

-200/120 |

| RTS 160 | 160,0 | 29,6 | 2,4 |

DIN4102: B2 EN 13501: Euroclasse E |

-200/120 |

| RTS 240 | 240,0 | 39,0 | 4,7 |

DIN4102: B2 EN 13501: Euroclasse E |

-200/120 |

| RTS 320 | 320,0 | 47,8 | 8,5 |

DIN4102: B2 EN 13501: Euroclasse E |

-200/120 |

| MD 600 | 600,0 | 96,0 | 22,0 |

DIN4102: B2 EN 13501: Euroclasse E |

-200/65 |